EDGE GRAIN or END GRAIN? That is the Question.

I just learned something about wooden cutting boards that I never knew before. And because a quality cutting board is a kitchen essential, and in the off-chance any of our Cook’n readers also do not know this, I thought it would be helpful to share this information.

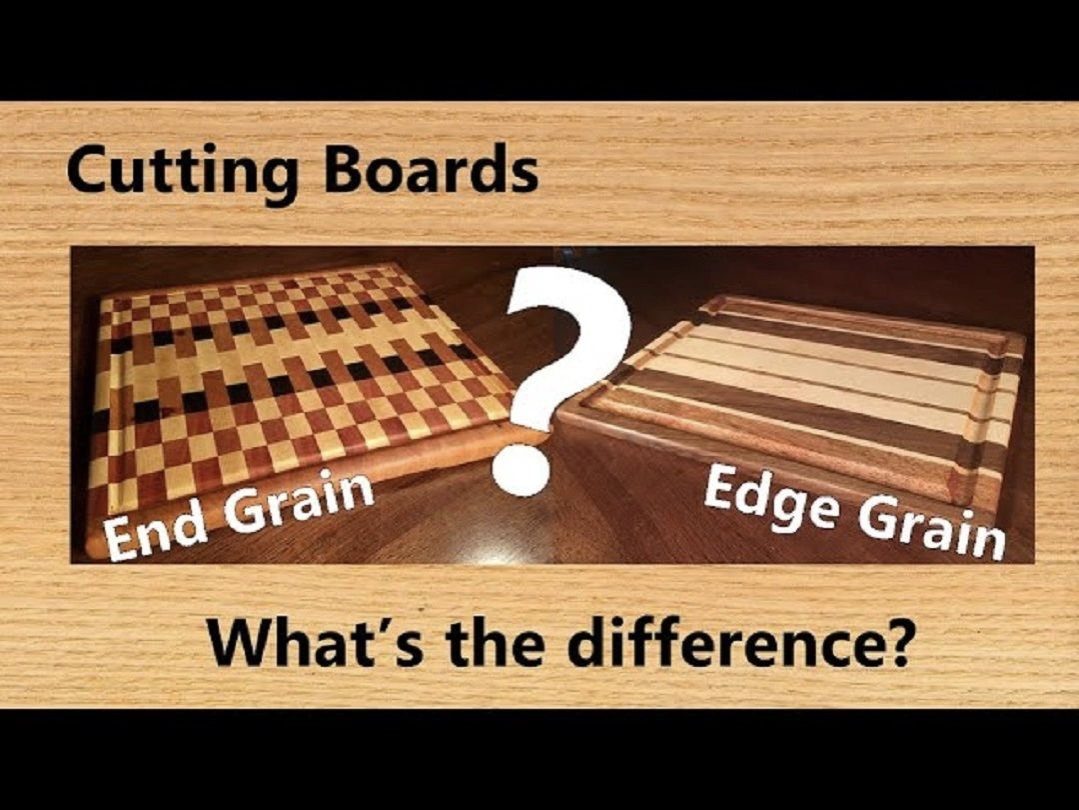

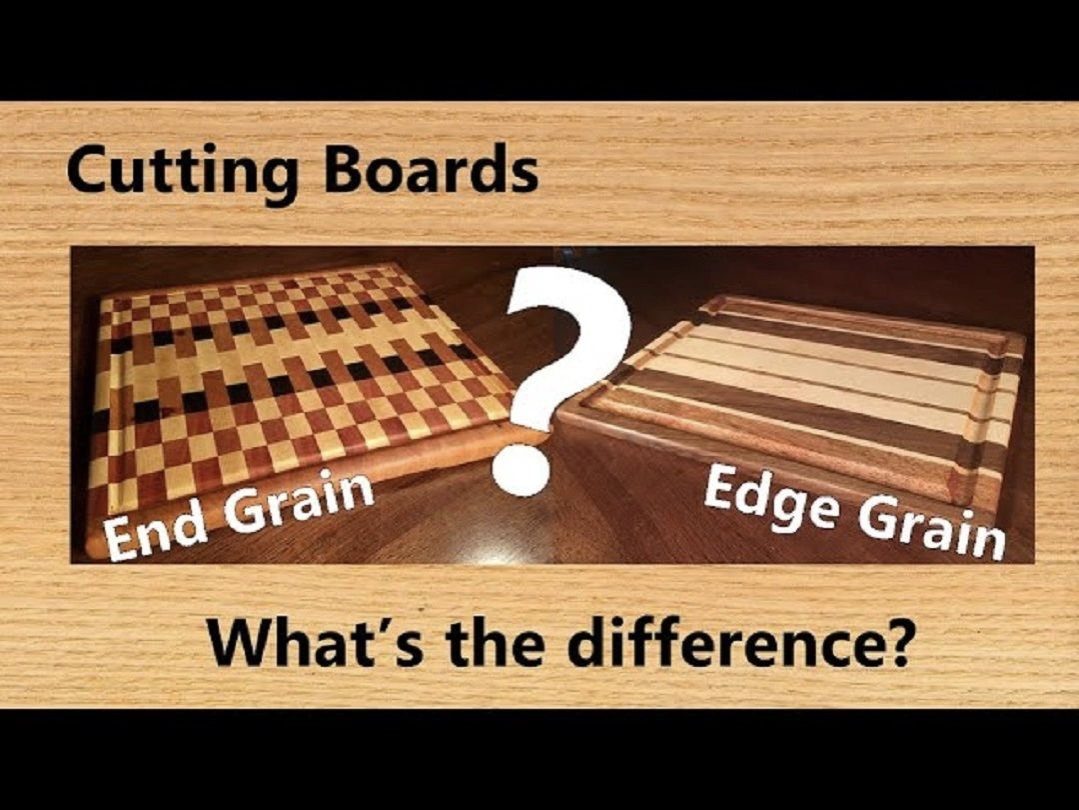

Here’s what I learned: Wooden cutting boards come in two different types—edge grain and end grain boards. I’ve noticed the differences, but always thought this was just about creative design. Turns out, grain orientation determines much more than the resulting looks of the board. Grain orientation (and the construction methods needed for each orientation) results in distinct advantages and disadvantages.

Let’s look at EDGE GRAIN construction first. These boards are the most common and affordable. They are formed by laying long strips of premium hardwood rails of maple, cherry or walnut side by side and gluing them together. The wood fibers run horizontally.

Edge grain cutting surfaces are considered more knife-friendly, compared to other materials like plastic or glass (an advantage). However, over time, you’ll notice visible knife marks (a disadvantage). These can easily be remedied, though, by sanding the board with the wood’s grain and applying a coat of quality food-grade wood oil (an important advantage).

Next, there’s END GRAIN construction. They can be stunning. They’re created by cutting short square pieces of maple, cherry or walnut hardwood and arranging them vertically and stood on end. End grain construction is more labor intensive than edge grain, so these boards typically cost more (a disadvantage).

The end grain boards demonstrate a self-healing process in that when a knife cuts into an end grain board’s surface, it slides in between the wood fibers. The fibers separate, and then close back up, keeping your knife edge sharper, longer (big advantage). However, an end grain board usually needs more oiling than an edge grain board, to maintain its appearance and to prevent drying out over repeated uses and washings (disadvantage).

When it comes down to it, both edge grain and end grain surface constructions are equally virtuous when dealing with food, safety, and durability. It’s just that, as mentioned above, end grain cutting boards have a more knife-friendly surface and resistance to deep cuts. And as mentioned above, it’s their higher price that’s the important consideration. Thus, if cost is a deal-breaker, the edge grain board may be the better choice.

In the final analysis, though, the thing to remember is that proper care and maintenance is THE key to extending the life of this important kitchen essential, whichever style you choose.

Here’s what I learned: Wooden cutting boards come in two different types—edge grain and end grain boards. I’ve noticed the differences, but always thought this was just about creative design. Turns out, grain orientation determines much more than the resulting looks of the board. Grain orientation (and the construction methods needed for each orientation) results in distinct advantages and disadvantages.

Let’s look at EDGE GRAIN construction first. These boards are the most common and affordable. They are formed by laying long strips of premium hardwood rails of maple, cherry or walnut side by side and gluing them together. The wood fibers run horizontally.

Edge grain cutting surfaces are considered more knife-friendly, compared to other materials like plastic or glass (an advantage). However, over time, you’ll notice visible knife marks (a disadvantage). These can easily be remedied, though, by sanding the board with the wood’s grain and applying a coat of quality food-grade wood oil (an important advantage).

Next, there’s END GRAIN construction. They can be stunning. They’re created by cutting short square pieces of maple, cherry or walnut hardwood and arranging them vertically and stood on end. End grain construction is more labor intensive than edge grain, so these boards typically cost more (a disadvantage).

The end grain boards demonstrate a self-healing process in that when a knife cuts into an end grain board’s surface, it slides in between the wood fibers. The fibers separate, and then close back up, keeping your knife edge sharper, longer (big advantage). However, an end grain board usually needs more oiling than an edge grain board, to maintain its appearance and to prevent drying out over repeated uses and washings (disadvantage).

When it comes down to it, both edge grain and end grain surface constructions are equally virtuous when dealing with food, safety, and durability. It’s just that, as mentioned above, end grain cutting boards have a more knife-friendly surface and resistance to deep cuts. And as mentioned above, it’s their higher price that’s the important consideration. Thus, if cost is a deal-breaker, the edge grain board may be the better choice.

In the final analysis, though, the thing to remember is that proper care and maintenance is THE key to extending the life of this important kitchen essential, whichever style you choose.

Alice Osborne

Alice Osborne

Weekly Newsletter Contributor since 2006

Email the author! alice@dvo.com